Objective:

(1) To explore advanced synthetic techniques

(2) To establish structure-function relationships

(3) To seek major breakthroughs from activity, stability, and cost

(4) To demonstrate the potential for large-scale applications

Capability:

(1) Nano-material synthesis with well-defined morphology

- Carrying out most of the preparation methods regarding liquid-phase chemical reaction

- Separation of nano-materials from liquid solvent via high-speed centrifuge (up to 16,000 rpm)

- Power drying via vacuum oven

- Calcination of as-synthesized material at various gas environment and high temperature (up to 1,200 °C)

(2) Half-cell tests to obtain the material activity and stability, and study the reaction mechanism

- Cyclic voltammetry (CV), Linear sweep voltammetry (LSV), Electrochemical impedance spectrum (EIS), Chronoamperometry, Chronopotentiometry, Corrosion Potential, etc.

Application:

(1) Alkaline anion exchange membrane fuel cell and electrolyzer (AAEMFC)

(2) Proton exchange membrane fuel cell and electrolyzer (PEMFC)

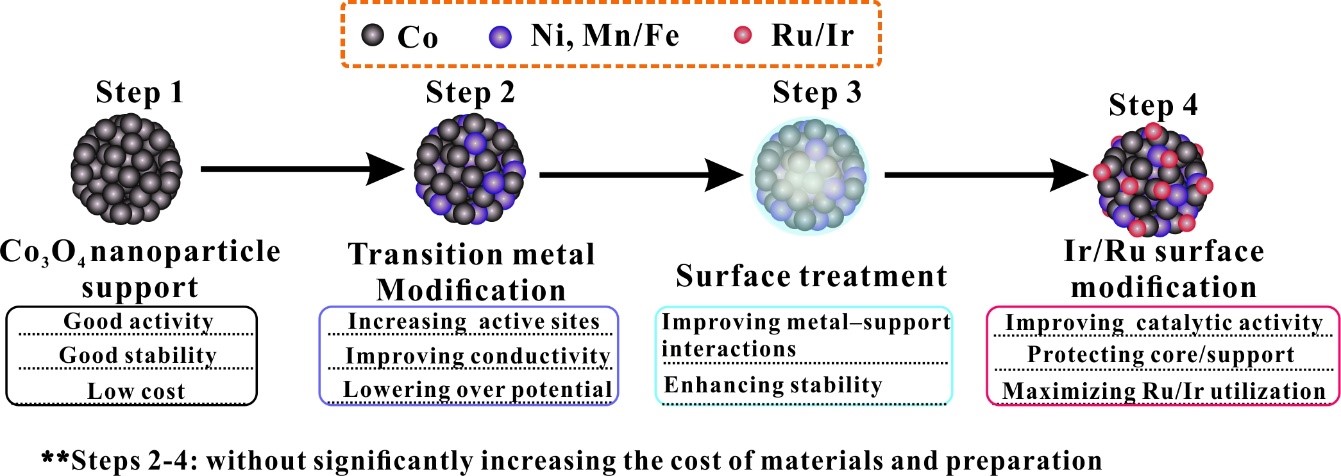

Approach (1): Nanocatalyst Powder

Example: Electrocatalysts for oxygen evolution reaction

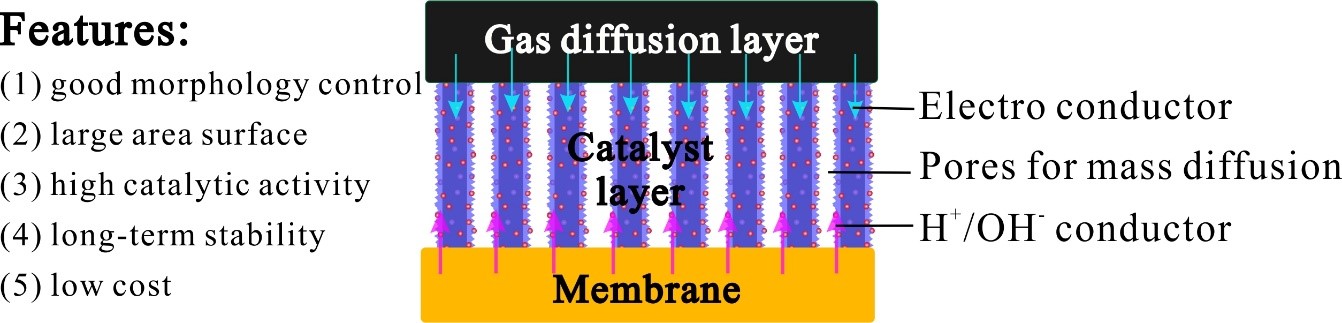

Approach (2): Ideal Electrode

Relevant Publications:

- Kakati, N, Li, G., Chuang, P. A., " Insights into the Ni/C-Based Thin-Film Catalyst Layer Design for Urea Oxidation Reaction in a Three-Electrode System,” ACS Appl. Energy Mater. 2021, https://doi.org/10.1021/acsaem.1c00607

- del Rosario, J. D., Li, G., Labata, M. F., Ocon, J. D., Chuang, P.A., "Unravelling the roles of alkali-metal cations for the enhanced oxygen evolution reaction in alkaline media,” Applied Catalysis B: Environmental 2021, https://doi.org/10.1016/j.apcatb.2021.119981

- Serraon, A. F., Del Rosario, J. D., Chuang, P. A., Chong, M. N., Morikawa, Y., Padama, A. B., Ocon, J., "Alkaline earth atom doping-induced changes in the electronic and magnetic properties of graphene: a density functional theory study." RSC Advances 11, no. 11 (2021): 6268-6283 https://doi.org/10.1039/D0RA08115A

- Labata, M. F., Li, G., Ocon, J. D., Chuang, P. A., "Insights on platinum-carbon catalyst degradation mechanism for oxygen reduction reaction in acidic and alkaline media," Journal of Power Sources (2020) https://doi.org/10.1016/j.jpowsour.2020.229356

- Li, G. F., Divinagracia, M., Labata, M. F., Ocon, J. D., Chuang, P. A., “Electrolyte-Dependent Oxygen Evolution Reactions in Alkaline Media: Electrical Double Layer and Interfacial Interactions.”, ACS applied materials & interfaces (2019): 11(37), 33748-33758. https://doi.org/10.1021/acsami.9b06889

- Musico, Y. L. F., Kakati, N., Labata, M. F., Ocon J. D., Chuang, P. A., "One-pot hydrothermal synthesis of heteroatom co-doped with fluorine on reduced graphene oxide for enhanced ORR activity and stability in alkaline media." Materials Chemistry and Physics 236 (2019): 121804. https://doi.org/10.1016/j.matchemphys.2019.121804 (Cited by 2)

- Li, G, Yang, D., Chuang, P. A., “Defining Nafion ionomer roles for enhancing alkaline oxygen evolution electrocatalysis,” ACS Catalysis 2018, http://dx.doi.org/10.1021/acscatal.8b02217 (Cited by 10)

- Geronia, R. M., Padama, A. A, Chuang, P. A., Chong M. N., Ocon, J. D, “Monatomic oxygen adsorption on halogen-substituted monovacant graphene, “ International Journal of Hydrogen Energy. 2018 Sep 13;43 (37):17673-81. https://doi.org/10.1016/j.ijhydene.2018.07.185

- Li, G., Chuang, P. A., “Identifying the forefront of electrocatalytic oxygen evolution reaction: electronic double layer,” Applied Catalysis B: Environmental 2018, https://doi.org/10.1016/j.apcatb.2018.08.037 (Cited by 15)

- Li, G., Anderson, L, Chen, Y, Pan M., Chuang, P. A., “New Insights into Evaluating Catalyst Activity and Stability of Oxygen Evolution Reactions in Alkaline Media,” Sustainable Energy & Fuels, 2017, https://doi.org/10.1039/C7SE00337D(Cited by 46)